Quick Definitions: Understanding the Manufacturing Models

OEM (Original Equipment Manufacturer)

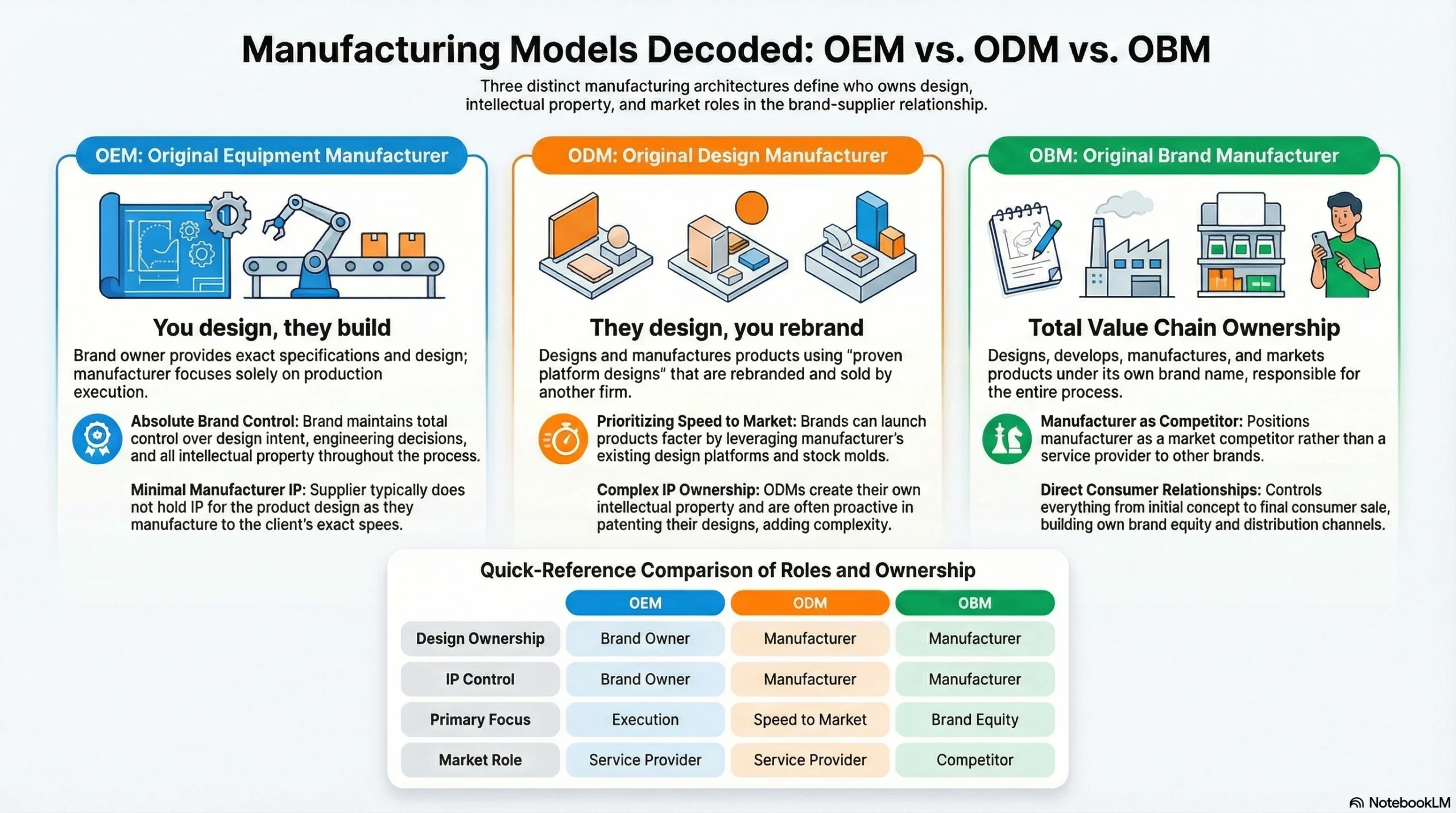

An OEM is commonly understood as a company that produces parts or equipment that may be marketed by another manufacturer. The term is used in several ways, which creates ambiguity in sourcing conversations. In packaging contexts, OEM typically describes a relationship where “you own the design/specification; the supplier manufactures to your exact specifications”. The brand maintains control over design intent, engineering decisions, and intellectual property, while the manufacturer focuses on production execution.

ODM (Original Design Manufacturer)

An ODM is a company that designs and manufactures a product that is eventually rebranded by another firm. In packaging ecosystems, ODMs often provide proven platform designs—sometimes with stock molds—that brands can customize and sell under their own brand identity. ODMs create their own intellectual property and are typically proactive in patenting their designs, which adds complexity around IP ownership. The ODM model emphasizes speed to market by leveraging existing design platforms and manufacturing knowledge.

OBM (Original Brand Manufacturer)

An OBM refers to a company that designs, develops, manufactures, and markets products under its own brand name. Unlike OEMs or ODMs that manufacture for other companies, an OBM takes full ownership and responsibility for the entire product development, production, and marketing process. In packaging supply chains, OBM represents a distinct market structure where the manufacturer becomes a brand owner rather than simply providing manufacturing services.

The OBM model is fundamentally different from OEM and ODM in that it positions the manufacturer as a competitor in the market rather than a service provider. An OBM company controls the entire value chain—from concept to consumer—and builds its own brand equity, distribution channels, and customer relationships.

Why OEM/ODM/OBM Decisions Matter More in 2026

Brand owners today face a packaging environment where “just getting a bottle made” is no longer the primary challenge. The critical pressures now are time-to-market speed, shelf differentiation, cross-market compliance, sustainability mandates, and supply chain resilience—all simultaneously.

Regulatory Pressure Intensifying

In 2026, packaging regulation has moved from voluntary sustainability commitments to enforceable standards. Extended Producer Responsibility (EPR) programs are entering operational stages, with producer responsibility organization appointments and fee modulation based on recyclability data. Chemical compliance has expanded significantly, with PFAS bans now applying not only to food containers but also to inks, coatings, labels, and strapping materials.

The European Union’s Single-Use Plastics Directive is pushing beauty brands toward compostable and recyclable packaging materials, making paper-based packaging, glass containers, and refillable formats more prevalent. Luxury brands including Chanel, Dior, and Lancôme are investing heavily in high-end sustainable packaging solutions using recyclable glass, aluminum cases, and bio-based plastics.

Supply Chain Complexity

Your OEM/ODM/OBM choice directly determines:

Who owns the design intent and engineering decisions: This affects your ability to modify, improve, or troubleshoot packaging over time

Who controls tooling and modifications: Tooling ownership determines whether you can switch suppliers or scale production across multiple regions

How fast you can sample and scale: Development timelines vary dramatically between models—digital-printed folding cartons can be ready in 5-14 days, while rigid specialty boxes may require 20-45 days

What happens if you need to switch suppliers: Without proper tooling ownership agreements, you may be locked into a single manufacturer

How you manage risk: This includes leakage, decoration defects, compatibility failures, and delivery volatility

This guide focuses on brand owners (not distributors or agents) and aims to provide neutral, experience-based insights on what these models look like in real packaging projects, where they typically fail, and how to choose a model aligned with your 2026 strategy.

First: Why These Terms Get Confusing in Packaging

To understand how Hainan fits into the existing free trade port hierarchy, we must first map the fundamental differences in institutional design. The following comparison synthesizes data from Hainan Provincial Government, Maritime and Port Authority of Singapore, Dubai Multi Commodities Centre, and World Bank Doing Business indicators.

What OEM Means in Packaging (and When It's the Right Choice)

How "OEM Packaging" Works in Real Projects

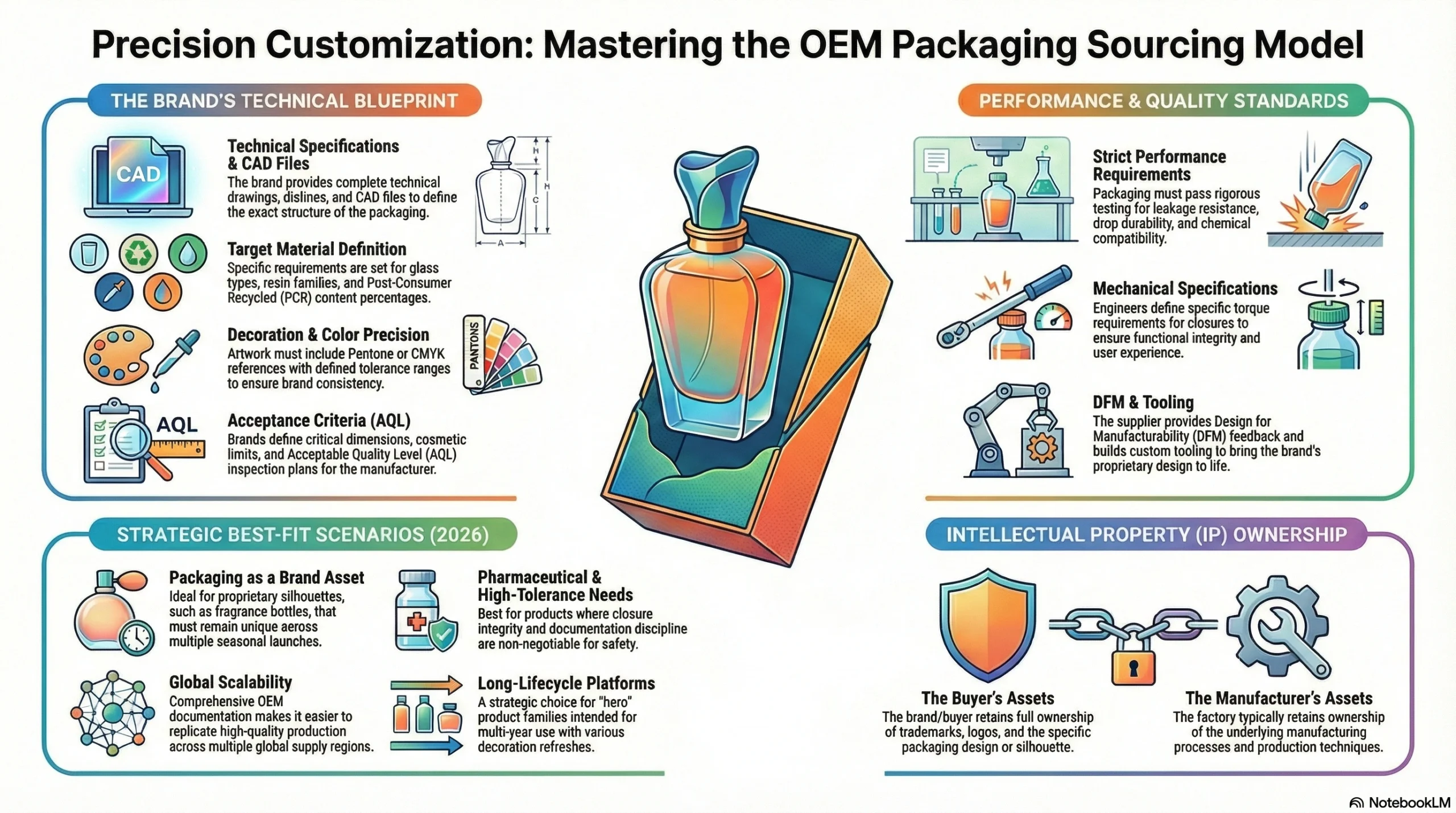

In brand sourcing conversations, OEM packaging typically means the brand owns the packaging concept (or hires an external design agency), defines the structure, and provides:

CAD files, dielines, or reference drawings: Complete technical specifications

Target materials: Glass type, resin family, PCR (post-consumer recycled content) requirements

Decoration artwork and color specifications: Pantone or CMYK references with tolerance ranges

Performance requirements: Leakage resistance, drop testing, chemical compatibility, torque specifications

Acceptance criteria: Critical dimensions, cosmetic limits, AQL (Acceptable Quality Level) inspection plans

The supplier manufactures to specification, provides DFM (Design for Manufacturability) feedback, builds tooling if needed, and runs production under the agreed quality plan. In OEM arrangements, intellectual property is usually clear: the buyer owns its branding (trademarks, logos, and packaging design), while the factory may own underlying manufacturing processes.

If your brand already has a strong packaging identity—a unique silhouette, signature base geometry, or proprietary closure feel—OEM is often the model that protects differentiation best because your design intent remains central.

OEM Best-Fit Scenarios

OEM tends to fit best when:

Your packaging is a brand asset: Example: A fragrance bottle silhouette that must remain proprietary across multiple markets and seasonal launches.

Performance constraints are strict: Pharmaceutical packaging where tolerances, closure integrity, and documentation discipline are non-negotiable.

You plan to scale globally: OEM documentation (proper engineering drawings, tolerances, testing specifications) makes it easier to replicate production across multiple supply regions.

You’re building a long lifecycle platform: A hero jar family you’ll reuse for years with multiple decoration refreshes.

A Practical OEM Workflow

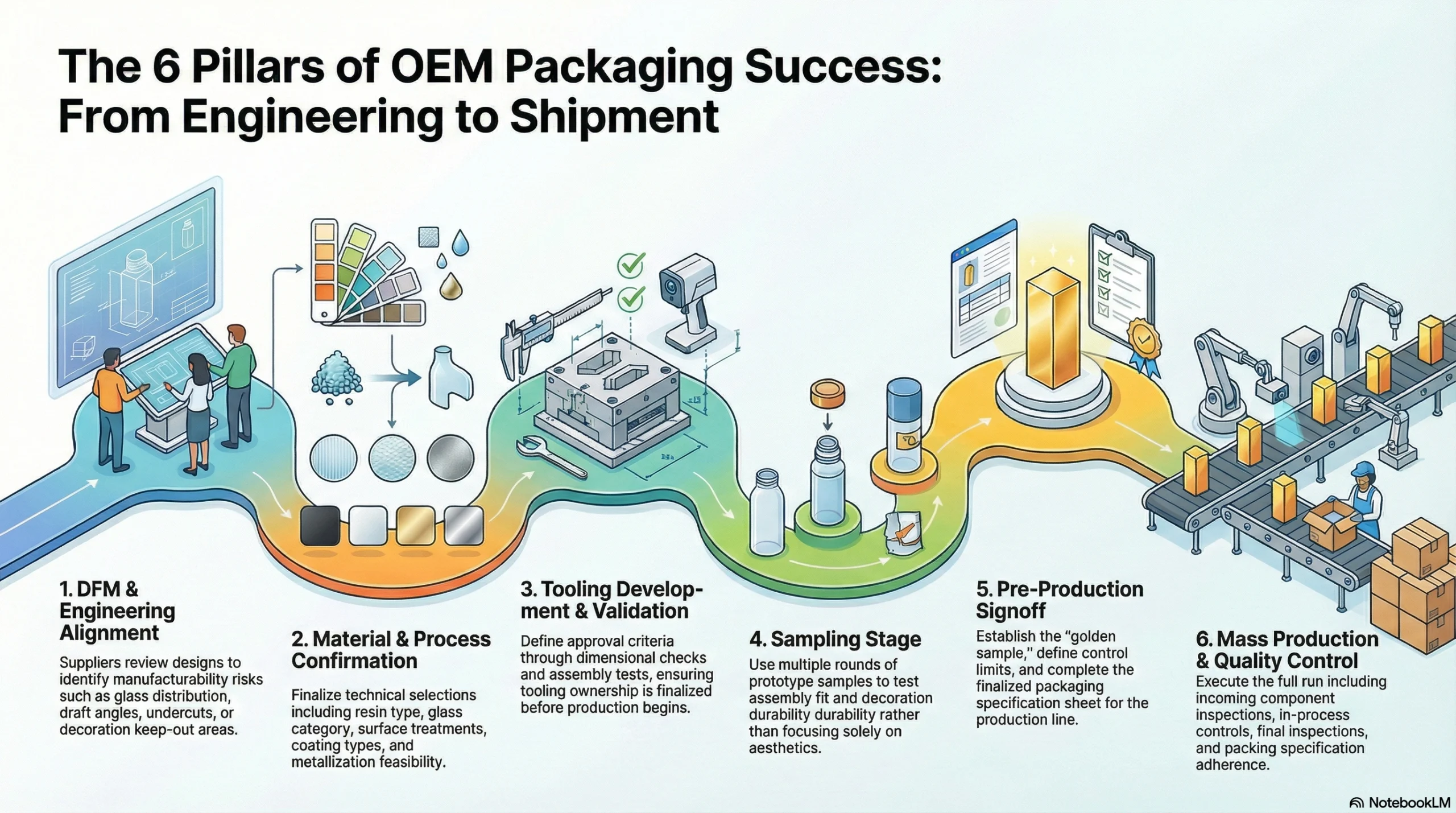

A healthy OEM packaging project typically follows these stages:

1. DFM/Engineering Alignment: Your supplier reviews your design and identifies manufacturability risks such as glass distribution, draft angles, undercuts, or decoration keep-out areas.

2. Material + Process Confirmation: Surface treatment, resin selection, glass category, coating type, metallization feasibility.

3. Tooling Development + Validation Plan: Define what “approval” means through dimensional checks, decoration trials, and assembly tests. Tooling ownership should be finalized before production begins or before paying tooling costs.

4. Sampling Stage: Prototype samples test assembly fit and decoration durability, not just aesthetics. Multiple rounds are common.

5. Pre-Production Signoff: Establish a golden sample, control limits, and finalized packaging specification sheet.

6. Mass Production + QC + Shipment Prep: Includes incoming component inspection, in-process controls, final inspection, and packing specifications.

OEM Advantages

Maximum differentiation and control: You decide structure, details, and tolerances

Clearer IP ownership: CAD files and tooling can be explicitly assigned through proper contracts

Better long-term repeatability: Once stabilized, OEM designs can scale with fewer surprises

OEM Trade-Offs

Upfront cost: Tooling and engineering iteration represent real costs, even when not itemized separately. Tooling costs for packaging can range from a few thousand dollars for simple molds to tens of thousands for complex multi-cavity or rigid specialty packaging.

Project management intensity: The brand must coordinate decisions quickly to avoid delays.

OEM Pitfalls Brand Owners Encounter

Over-designing before DFM: Brands sometimes lock aesthetics before understanding wall thickness, decoration feasibility, or assembly constraints.

Specification gaps causing rework: “Matte white cap” is not a specification—you need resin type, texture standard, color standard, and pass/fail criteria.

Tolerance stacking: If bottle neck, pump, and collar are produced by different factories, small tolerances can stack into leakage or misalignment.

OEM Takeaway: Choose OEM when differentiation + control + long-term platform value outweigh the speed benefits of ODM.

What ODM Means in Packaging (and Why It's Often the Fastest Win in 2026)

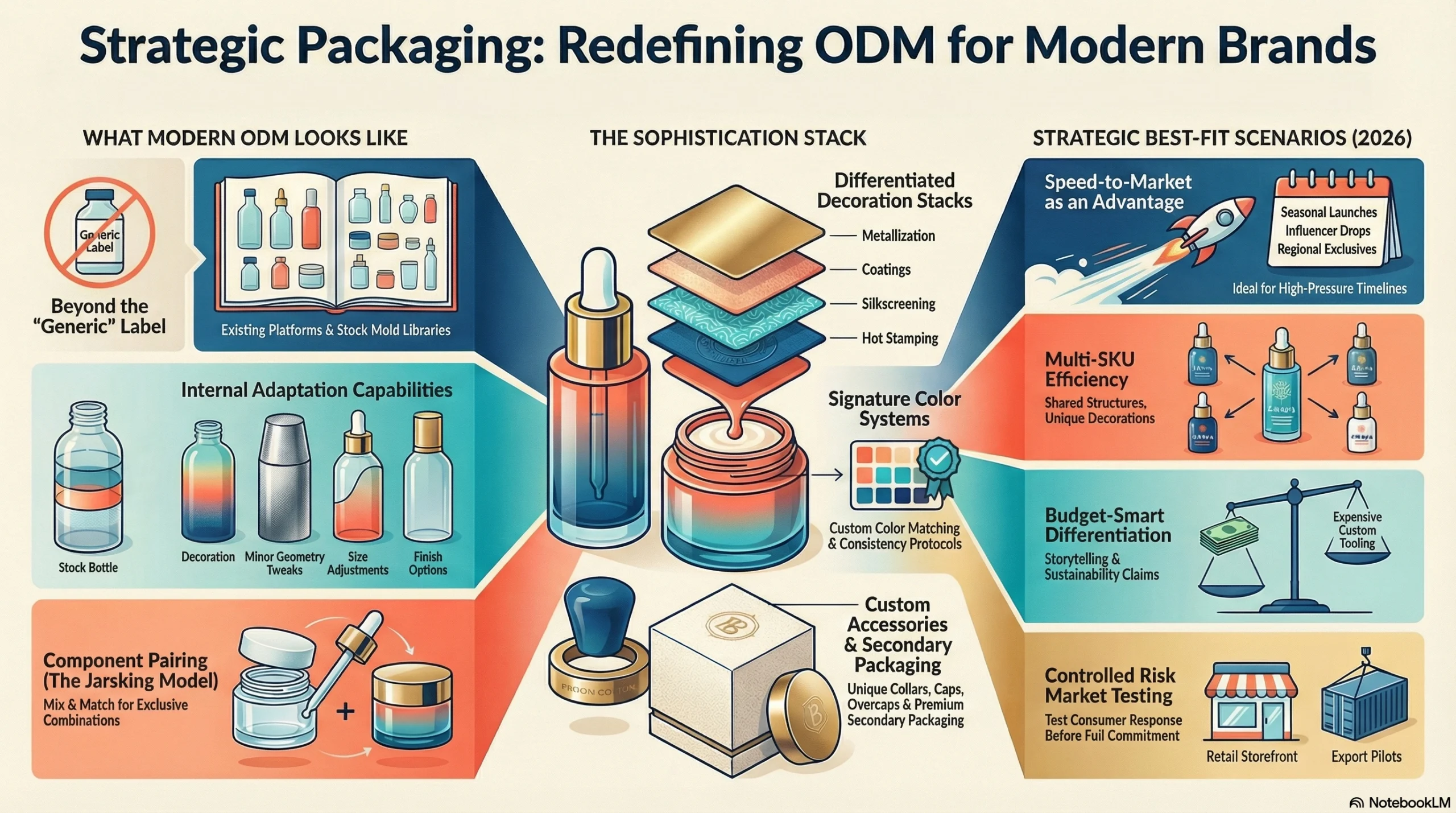

What ODM Looks Like in Packaging

In packaging, ODM commonly means the supplier has:

Existing bottle, jar, or closure platforms

Sometimes a stock mold library

Internal capability to adapt through decoration, minor geometry tweaks, size adjustments, finish options, and accessory swaps

ODM is not automatically “generic.” A sophisticated ODM approach can produce highly brand-appropriate packaging through:

Differentiated decoration stacks: Coatings + metallization + silkscreen + hot stamping

Signature color systems: Custom color matching and consistency protocols

Custom accessories: Collars, caps, overcaps that create unique combinations

Secondary packaging: That completes the premium experience

Jarsking, for example, demonstrates how ODM suppliers can offer component pairing—mixing and matching bottles, droppers, caps, and collars from their catalogue to create exclusive combinations with eco-friendly decoration options.

ODM Best-Fit Scenarios

ODM often fits best when:

Speed-to-market is your competitive advantage: Seasonal launches, influencer drops, regional exclusives.

You need multiple SKUs fast: Skincare line extensions where structure can be shared but decoration differentiates variants.

Budget favors “smart differentiation”: Use proven platforms and invest budget in decoration, storytelling, and defensible sustainability claims.

You’re testing a market: An export pilot where you want controlled risk before committing to full custom tooling.

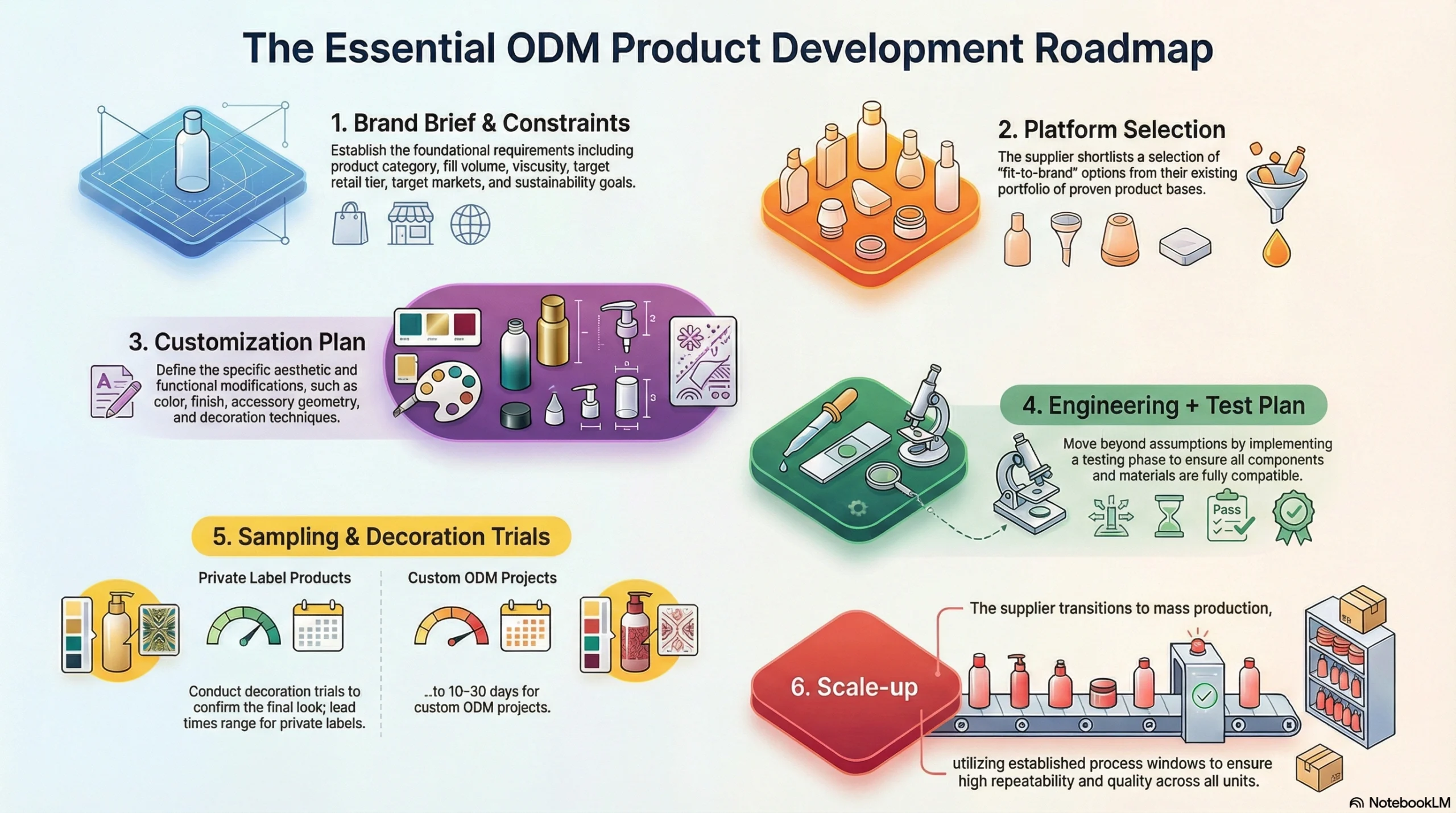

A Practical ODM Workflow

A strong ODM supplier typically runs this process:

1. Brand brief and constraints: Category, fill volume, viscosity, target retail tier, markets, sustainability targets

2. Platform selection: Shortlisting a few “fit-to-brand” options from their existing portfolio

3. Customization plan: Defining what gets customized (color, finish, accessory geometry, decoration)

4. Engineering + test plan: Compatibility assumptions get tested, not guessed

5. Sampling: Decoration trials are often the critical path. Lead times vary: private label products may take 5-14 days, while custom ODM projects might require 10-30 days.

6. Scale-up: Supplier drives repeatability using established process windows

ODM Advantages

Speed: You’re leveraging proven manufacturing knowledge and sometimes existing molds, reducing development time significantly.

Lower development risk: Platforms may already be validated in similar use cases.

Supplier expertise built in: Good ODM suppliers know what fails in transit, what scratches, what colors shift, and what leaks based on their platform experience.

ODM Trade-Offs

Uniqueness ceiling: The base structure may not be exclusive unless you negotiate it contractually.

IP and switching suppliers: You must clarify what intellectual property you can take with you if you move production. ODMs create and patent their own IP, which creates complexity around ownership.

“Looks premium” vs “performs premium”: ODM can create beautiful samples quickly, but you still need performance validation.

ODM Pitfalls

Assuming compatibility without test data: The most common late surprise is leakage, actuator mismatch, dip tube issues, or formula interaction with coatings and liners.

Treating decoration as “final step”: Decoration can drive yield loss and extend lead time. In premium packaging, decoration is often the critical path, not an afterthought.

Underestimating the “me-too” risk: If your only differentiation is a common stock bottle and standard print, you may be indistinguishable at shelf distance.

ODM Takeaway: Choose ODM when time-to-market + controlled cost + proven manufacturability are the priority, and you’re comfortable differentiating via finishing, accessories, and system design.

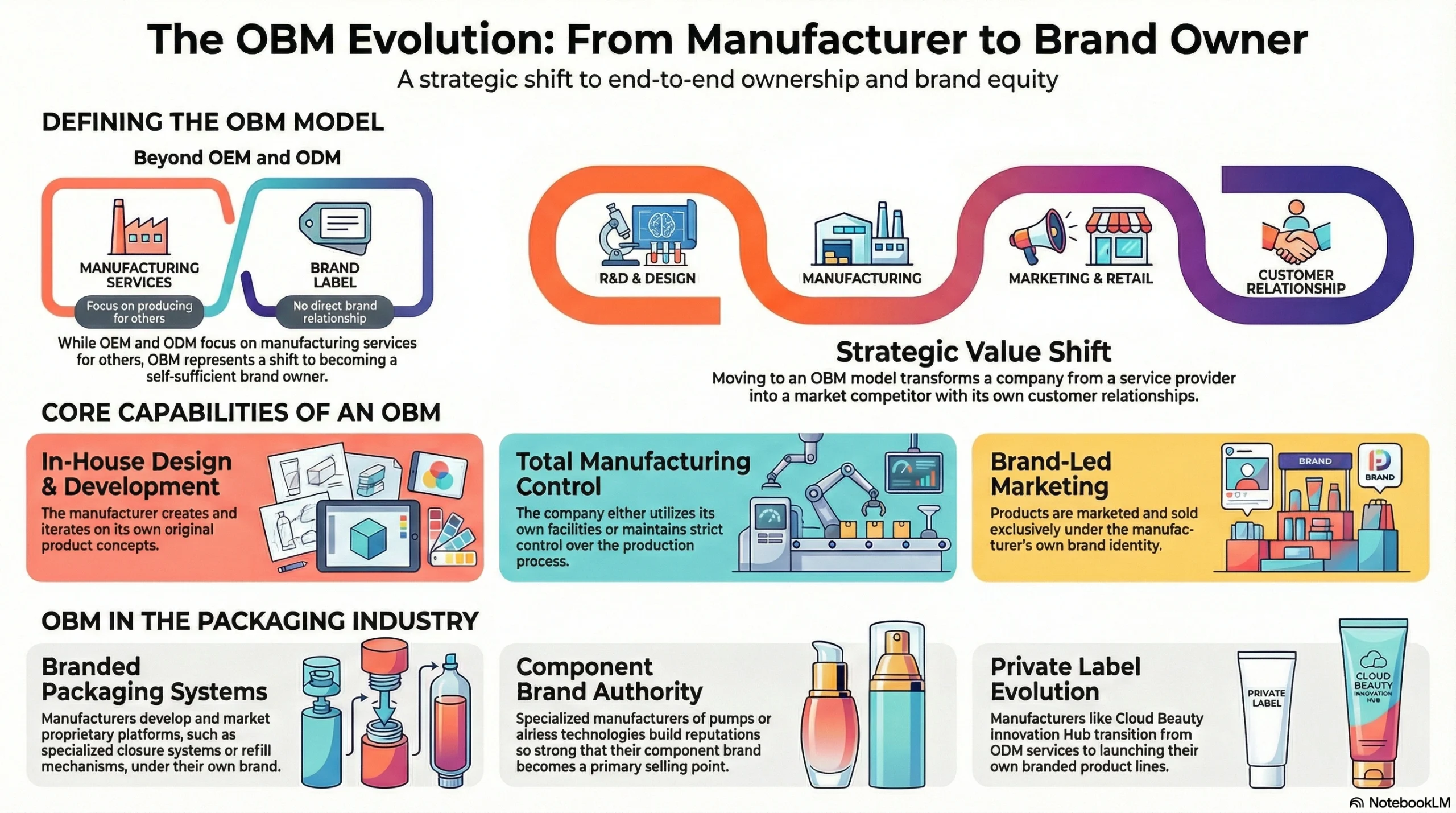

What OBM Means for Packaging Buyers

Understanding OBM as a Business Model

OBM (Original Brand Manufacturer) represents a fundamentally different relationship than OEM or ODM. While OEM and ODM are service models where manufacturers produce for other brands, OBM describes a company that has evolved from being a contract manufacturer to becoming a brand owner itself.

An OBM company:

Designs and develops its own products

Manufactures those products in its own facilities (or controls the manufacturing)

Markets and sells products under its own brand name

Builds its own distribution channels and customer relationships

Owns the complete value chain from R&D to retail

This evolution from manufacturing service provider to brand owner represents a significant strategic shift that changes the competitive dynamics.

OBM in the Packaging Industry Context

For packaging buyers, OBM manifests in several ways:

Branded Packaging Systems: Some manufacturers develop proprietary packaging platforms or systems and market them under their own brand. For example, specialized closure systems, refill mechanisms, or innovative dispensing technologies that carry the manufacturer’s brand identity.

Component Brands: Certain packaging component manufacturers have built such strong reputations that their brand becomes a selling point. Think of specialized pump systems, airless packaging technologies, or proprietary glass finishing techniques that are marketed under the manufacturer’s name.

Private Label Evolution: Some manufacturers that started as pure ODM suppliers have evolved into OBM players by launching their own branded product lines while continuing to manufacture for other brands. Cloud Beauty Innovation Hub, for instance, specializes in private label services while offering OBM solutions.

Key Differences: OBM vs ODM vs OEM

| Aspect | OBM | ODM | OEM |

|---|---|---|---|

| Brand Ownership | Manufacturer owns and promotes its own brand | Limited control; manufactures for client brands | No brand ownership; manufactures for client brands theodmgroup |

| Design Control | Complete control over product design and identity | Specializes in design based on platform; client customizes | Client provides specifications; manufacturer executes theodmgroup+1 |

| Market Position | Competes directly in the market as a brand | Service provider to brands | Service provider to brands globalsources+1 |

| Revenue Model | Brand equity + product sales | Manufacturing fees + design fees | Manufacturing fees globalsources |

| Distribution | Owns distribution channels | Client handles distribution | Client handles distribution theodmgroup |

| Customer Relationship | Direct relationship with end consumers | Relationship with brand clients | Relationship with brand clients globalsources |

| IP Strategy | Builds and protects own IP portfolio aggressively | Creates and patents platform IP; licenses to clients | Limited IP; executes to client specs harris-sliwoski |

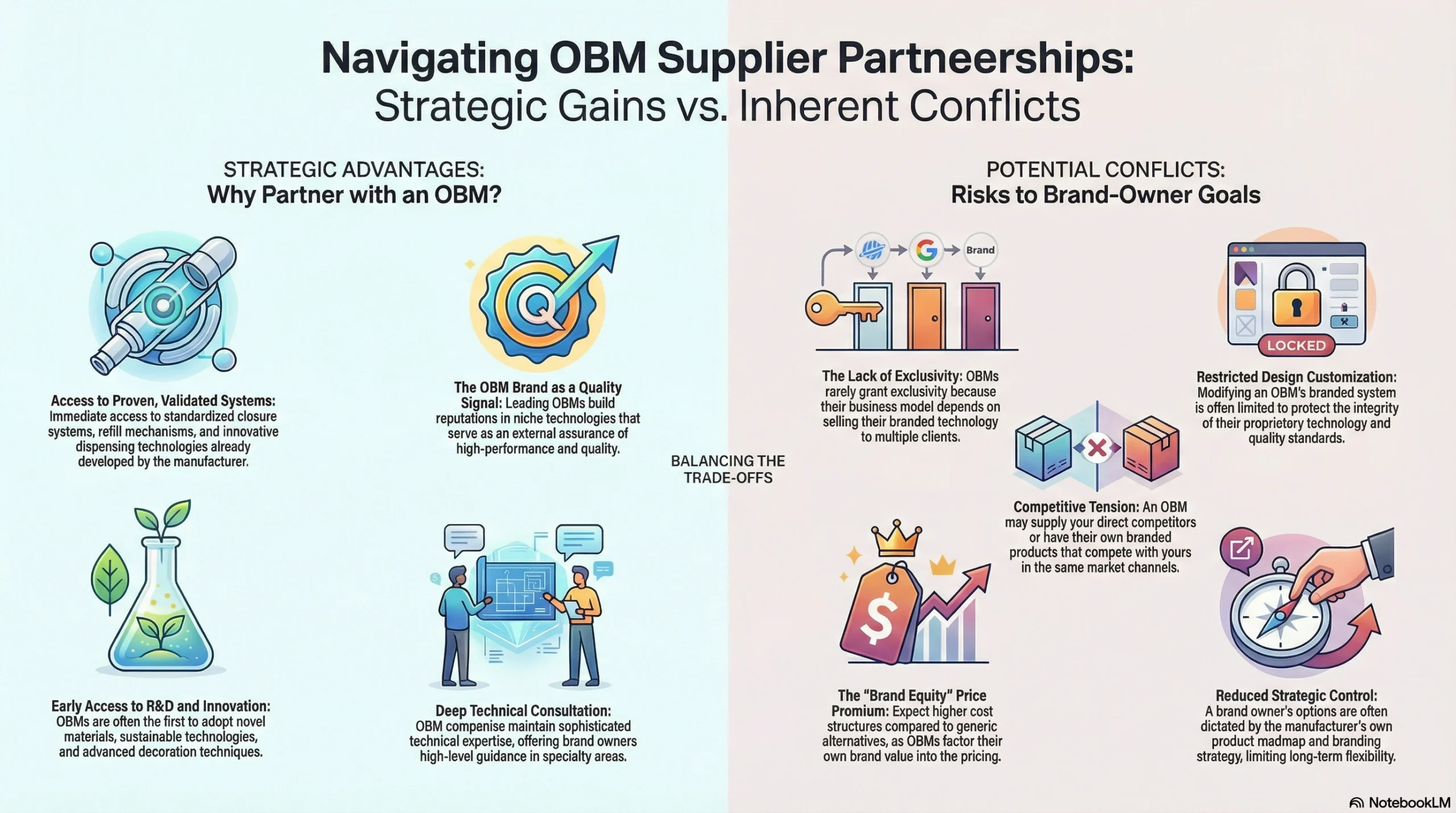

When OBM-Type Suppliers Can Help Brand Owners

Proven Systems Access: If you want a validated refill mechanism, standardized closure system, or innovative dispensing technology that a manufacturer has developed and branded, partnering with an OBM can provide immediate access to proven solutions.

Quality Assurance: Some OBM suppliers have built such strong reputations in specific technologies (e.g., airless packaging, high-performance pumps) that their brand serves as a quality signal.

Innovation Leadership: OBM players often invest heavily in R&D because they’re building their own brand equity. This can make them early adopters of new materials, sustainable technologies, or novel decoration techniques.

Technical Expertise: Because OBM companies market their own products, they typically maintain deep technical expertise in their specialty areas and can provide sophisticated consultation.

When OBM May Conflict with Brand-Owner Goals

Exclusivity Limitations: If an OBM is building its own brand around a packaging technology or system, they’re unlikely to grant exclusivity. Their business model depends on selling their branded system to multiple clients.

Design Differentiation: You may have limited ability to customize or modify an OBM’s branded system without compromising what makes it valuable—their proprietary technology and quality standards.

Competitive Positioning: There’s an inherent tension when your packaging supplier is also a brand owner. They may serve your direct competitors, or their own branded products might compete with yours in certain channels.

Cost Structure: OBM suppliers are building their own brand equity into their pricing. You may pay a premium for their branded systems compared to generic OEM/ODM alternatives.

Control and Flexibility: With OBM relationships, the manufacturer’s roadmap and branding strategy can influence what you can buy and how you can use it.

The OBM Evolution Path: Why Manufacturers Pursue It

Understanding why manufacturers pursue OBM helps brands make better sourcing decisions:

Higher Margins: Brand ownership typically delivers better margins than contract manufacturing, where competition drives prices down.

Market Intelligence: Selling directly to consumers provides valuable data about preferences, trends, and pain points that pure manufacturers don’t access.

Reduced Dependency: OBM reduces reliance on any single client and provides revenue diversification.

Innovation Incentive: When manufacturers own brands, they’re more motivated to invest in breakthrough innovations rather than incremental improvements.

Competitive Positioning: OBM represents the “high end” of the manufacturing value chain, commanding respect and premium positioning.

Real-World OBM Examples in Related Industries

While OBM is less common as a packaging service model, understanding examples from adjacent industries clarifies the concept:

Sony: Developed Original Blended Material (OBM), a proprietary paper material for product packaging designed for true material circulation. Sony controls the design, production, and branding of this packaging solution, representing an OBM approach to packaging material innovation.

Component Manufacturers: Specialized pump, closure, or airless packaging technology companies that market their innovations under their own brand names while also producing for beauty brands.

Private Label to Brand Evolution: Hair care and beauty manufacturers that started as pure ODM/private label suppliers but launched their own branded product lines while continuing contract manufacturing.

Strategic Considerations for Brand Owners Evaluating OBM Relationships

Assess Strategic Fit: Does the OBM supplier’s branded system authentically fit your brand positioning, or will it feel like a compromise?

Evaluate Lock-In Risk: How dependent will you become on this supplier’s proprietary system? What’s your exit strategy?

Understand IP Boundaries: Be crystal clear about what IP you’re licensing versus owning when you incorporate an OBM’s branded system.

Compare Total Cost: An OBM’s branded system might have higher per-unit costs but could reduce development time and risk—model the total cost of ownership.

Check Competitive Dynamics: Who else uses this OBM’s systems? Will you be sharing packaging architecture with competitors?

OEM vs ODM vs OBM: Side-by-Side Comparison (Brand Owner View)

| Decision Factor | OEM (Brand-Led Design) | ODM (Supplier-Led Platform) | OBM (Supplier Brand-Led) |

|---|---|---|---|

| Who drives design? | Brand or its design agency | Supplier platform; brand customizes | Supplier theodmgroup+1 |

| Speed to market | Medium–slow at start (10-45 days) | Fast (5-30 days) | Fast (standardized) winpackprinting |

| Upfront cost | Higher (tooling/development) | Lower–medium | Lower ferriot+1 |

| Differentiation potential | Highest | Medium–high (via decoration/accessories) | Lower (often standardized) theodmgroup+1 |

| Best for | Hero SKUs, long lifecycle, strict requirements | Fast launches, many SKUs, controlled risk | Buying proven systems/standard lines theodmgroup+1 |

| IP ownership | Clear brand ownership with proper contracts | Complex; platform IP remains with supplier | Supplier owns all IP harris-sliwoski+1 |

| Tooling control | Brand can own tooling | Typically supplier-owned | Supplier-owned harris-sliwoski+1 |

| Exclusivity potential | High (if contracted) | Negotiable | Low theodmgroup+1 |

| Key risk | Longer iteration cycles | IP clarity + “me-too” risk | Limited customization + dependency theodmgroup+1 |

The 2026 Decision Framework

How to Choose the Right Model

1) How Unique Does Your Packaging Need to Be?

Consider:

Is your packaging a core component of brand recognition (signature silhouette, tactile cues)?

Are you in a category where shape equity matters (fragrance, premium skincare)?

Will your packaging drive purchase decisions or primarily serve functional needs?

If yes → lean OEM (or ODM with significant customization + contractual exclusivity).

2) What Is Your Deadline—and Consequence of Missing It?

If the penalty for delay is high (campaign timing, retailer slotting deadlines), lean ODM or hybrid. A practical approach many successful brands use: ODM for launch speed, then OEM development for “version 2.0” once product-market fit is proven.

3) How Strict Are Your Performance and Compliance Constraints?

Pharmaceutical and dermocosmetic applications often demand robust documentation and tighter controls. With EPR programs entering operational stages and fee modulation based on recyclability data launching in 2026, compliance documentation is no longer optional.

Choose the model that ensures traceability, change control, and repeatability—this can be either OEM or ODM, depending on the supplier’s system maturity.

4) What Are Your Volumes and SKU Complexity?

Many SKUs + uncertain forecast → ODM can reduce risk

Stable, high-volume hero SKU → OEM can amortize tooling and build long-term brand assets

5) What Internal Capability Do You Have?

Be honest about internal resources:

Without internal packaging engineering capacity: ODM can reduce your management burden—if the supplier’s process is mature

With a strong packaging team: OEM can unlock deeper differentiation

6) Are You Considering a Supplier’s Proprietary Branded System?

If you’re evaluating incorporating a manufacturer’s proprietary packaging technology or branded system into your product architecture, OBM dynamics become relevant.

Key questions to consider:

Is the technology truly differentiated? Does the OBM supplier’s branded system (refill mechanism, dispensing technology, sustainable material innovation) offer a competitive advantage you cannot easily replicate?

Does it align with your brand positioning? Will using a supplier’s branded packaging system enhance or dilute your brand identity? Premium beauty brands must ensure that shared systems don’t compromise exclusivity perception.

What are the dependency risks? If you build your product architecture around an OBM’s proprietary system, how dependent will you become? What happens if they discontinue the technology, raise prices significantly, or serve your direct competitors?

Can you achieve strategic differentiation elsewhere? If you use an OBM’s standardized system, you must differentiate through formula, marketing, or secondary packaging rather than primary structure.

Experience-Based Scenarios Across Categories

Scenario A: Skincare Brand Launching 12 SKUs in Two Regions

Goal: Fast entry + cohesive shelf presence across multiple sizes

What works well:

ODM bottle/jar platforms for speed and consistency

Invest in strong decoration systems (color coding + finishes that read premium)

Standardize threads/closures to reduce compatibility problems

Where it can fail:

Underestimating decoration lead time (often the critical path)

Not locking a “golden sample” standard early, leading to batch-to-batch shade drift

Scenario B: Fragrance Brand Launching a Hero EDP Bottle

Goal: Ownable silhouette + luxury weight + high decoration quality

What works well:

OEM for bottle structure and base geometry

Early engineering work on decoration: coatings, metallization, multi-pass silkscreen

Tight control of neck finish + pump pairing

Where it can fail:

Tooling iteration cycles not aligned with marketing timelines

Assuming every decoration finish scales the way the sample looks (yield and scratch resistance matter at production scale)

Scenario C: Pharma/OTC Brand Expanding to New Markets

Goal: Reliable functionality + documentation + supply continuity

What works well:

OEM-style documentation discipline even if using some ODM components

Conservative material choices with proven compatibility

Clear change control (any resin/liner/process change triggers revalidation)

Where it can fail:

Switching component suppliers without re-testing the system as a whole

Not planning for long lead-time components (certain pumps/liners)

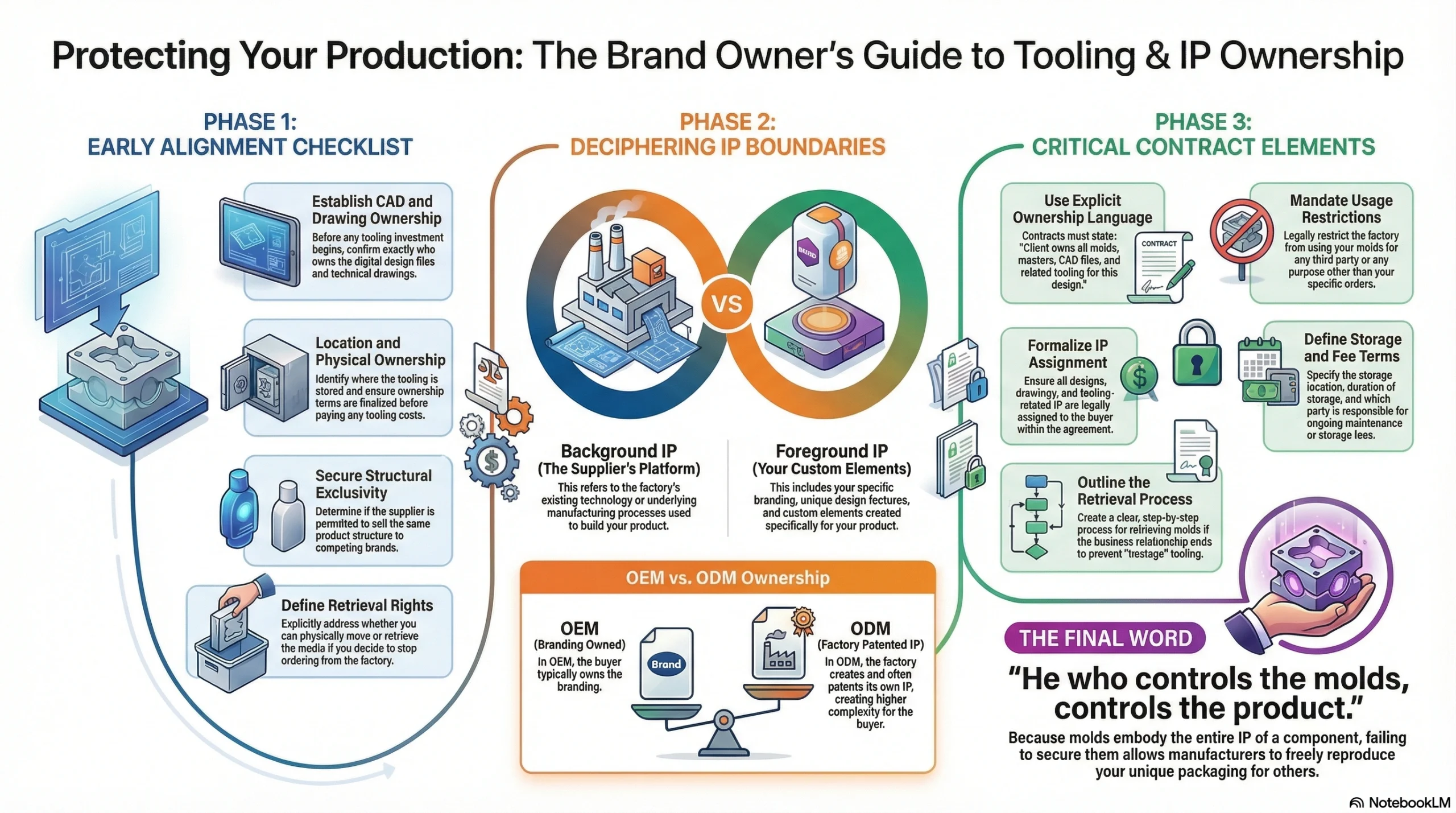

IP, Exclusivity, and Supplier Switching: What to Clarify Early

Both ODM and OEM can work well—if you define ownership and rights clearly before tooling investment begins.

Key Questions to Align (Brand Owner Checklist)

Who owns the CAD files/drawings?

Who owns the tooling (and where is it stored)? Ideally, tooling ownership terms should be finalized before production begins or before paying tooling costs.

If you stop ordering, can you retrieve the molds? This must be explicitly addressed in contracts.

Can the supplier sell the same structure to other brands?

What is considered the supplier’s background IP (their platform) versus your foreground IP (your custom elements)? In OEM arrangements, the buyer typically owns branding while the factory may own underlying manufacturing IP. ODMs create and patent their own IP, adding complexity.

Critical Contract Elements for Tooling

Proper tooling agreements should include:

Explicit ownership language: “Client owns all molds, masters, CAD files, and related tooling for this design”

Usage restrictions: “Factory may only use molds for [Brand Name] orders and may not produce for any third party”

Storage terms: Location, duration, and who pays ongoing storage fees

IP assignment: All designs, drawings, and tooling-related IP belong to the buyer

Retrieval rights: Clear process for mold retrieval if relationship ends

The molds often embody the entire intellectual property in a packaging component, so the party that owns or controls the IP in the molds essentially controls the product. Without proper agreements, molds can effectively become “open source,” allowing your manufacturer to freely reproduce your packaging.

Sustainability and Circular Design in 2026: How It Influences OEM/ODM Choices

Sustainability is not just a material choice in 2026—it changes supply availability, decoration options, assembly decisions (mono-material versus mixed), and refill/replace architecture.

Where ODM Can Accelerate Sustainability

If your supplier already has:

PCR-ready platforms

Recyclable component families

Proven refill systems

You can move faster by adapting a proven architecture rather than inventing new solutions. Brands like L’Oréal and L’Occitane have successfully transitioned to flexible and refillable packaging systems, often leveraging ODM platforms with sustainable materials.

Where OEM Is Still Essential

If your sustainability strategy requires:

Unique refill mechanics

Proprietary replaceable systems

Structural redesign to reduce weight while maintaining premium feel

OEM-level design control is often needed. Sony‘s development of Original Blended Material demonstrates how OEM approaches enable breakthrough sustainable packaging innovations.

2026 Sustainability Compliance Reality

Extended Producer Responsibility programs are entering operational stages, with producer responsibility organization appointments and modulation of fees based on recyclability data. Chemical compliance has expanded significantly, with PFAS bans now applying to inks, coatings, labels, and strapping materials—not just primary containers.

Your OEM/ODM choice must account for these compliance requirements, as they affect material selection, decoration processes, and documentation needs.

Buyer's Checklist: What to Ask Your Packaging Partner

Before NDA (Fit and Capability)

What categories do you produce most (skincare, fragrance, pharma)?

What decoration processes are in-house versus outsourced?

How do you handle sampling timelines and iteration loops?

What are your typical MOQs and lead times for projects like ours?

After NDA (Files and Engineering)

Can you provide a DFM review with identified risks?

What tests do you recommend for our use case?

What are the critical tolerances and how do you control them?

What are your tooling ownership terms?

During Sampling

What are the pass/fail criteria for decoration durability?

How will you control color across production lots?

What is the golden sample process?

Can you provide process window data for critical finishes?

Before Mass Production

What is the incoming inspection plan for components?

What changes require approval (materials, processes, sub-suppliers)?

How do you handle corrective actions if defects appear?

How do you manage EPR compliance and recyclability documentation?

Conclusion: Choosing OEM vs ODM vs OBM Is a Strategy Decision, Not a Label

OEM, ODM, and OBM are helpful concepts—but your best 2026 outcome comes from aligning responsibilities and risks, not memorizing acronyms.

Choose OEM when packaging is a long-term brand asset and you need maximum control, differentiation, and IP ownership.

Choose ODM when speed, proven platforms, and efficient customization matter most—and you’re prepared to manage IP boundaries and differentiation carefully through decoration and accessories.

Understand OBM as a market structure where the supplier becomes a brand owner with its own strategic agenda; it’s relevant for understanding supplier dynamics and evaluating proprietary branded systems, but less central for most brand owners sourcing packaging.

The packaging landscape in 2026 demands that brand owners think beyond simple manufacturing relationships. Success requires understanding how design responsibility, tooling ownership, IP boundaries, compliance obligations, and sustainability mandates intersect with your specific brand strategy.

Whether you choose OEM, ODM, or a hybrid approach, the critical factors remain the same: clear contractual agreements on IP and tooling ownership, robust quality systems, sustainable material strategies aligned with emerging regulations, and supplier partnerships that support both your launch timeline and long-term brand vision.

FAQs

OEM (Original Equipment Manufacturer): You design it, they make it. The brand owns the design and specifications while the supplier manufactures to your exact requirements.

ODM (Original Design Manufacturer): They design it, you customize it. The supplier provides existing platform designs that you customize through decoration, colors, and accessories.

OBM (Original Brand Manufacturer): They design and brand it. The manufacturer sells products under their own brand name, like branded refillable systems you can license or use.

In packaging, OBM appears as:

Branded refillable systems (like Loop’s reusable packaging platform)

Proprietary packaging technologies marketed under the manufacturer’s name

Specialized component brands (premium pumps, airless systems)

OBM makes sense when:

You need proven refillable/reusable infrastructure quickly

The manufacturer’s branded technology offers genuine competitive advantage

Speed and sustainability credentials matter more than structural exclusivity

You want to avoid the cost and time of developing proprietary systems

Yes—and most successful 2026 launches do exactly this.

Common hybrid approaches:

Example 1: Premium Skincare Line

OEM: Custom hero jar structure (unique brand asset)

ODM: Proven pump/closure components

OBM: Branded sustainable material system for eco-credentials

Example 2: Refillable Beauty Product

OBM: Refillable platform for infrastructure

ODM: Customized colors and finishes

OEM: Custom secondary packaging for brand differentiation

Example 3: Fragrance Launch

OEM: Proprietary bottle silhouette

ODM: Standard cap from supplier platform

OBM: Branded premium pump system

Why hybrid works:

Balances speed, cost, differentiation, and risk

Invests budget where it matters most (hero elements get OEM, accessories get ODM)

Leverages specialized expertise (OBM for complex technologies)

Reduces development time while maintaining brand uniqueness

Key to success: Clear documentation of what you own (OEM elements), what you license (ODM platforms), and what dependencies you’re accepting (OBM systems).

For OEM:

Get written contracts stating you own all design and tooling IP

Include non-compete clauses preventing similar designs for competitors

Specify tooling ownership and retrieval rights

Register patents and trademarks in relevant jurisdictions

For ODM:

Understand the supplier owns the base platform design

Negotiate exclusivity terms if needed

Clarify what custom elements you own (decoration, colors, accessories)

Document what’s yours versus the supplier’s platform

For OBM:

Recognize you’re licensing or using the manufacturer’s branded system—you don’t own the core technology

Negotiate clear usage rights: geographic scope, duration, category exclusivity

Document what happens if the supplier discontinues the system or changes terms

Protect only what you can own: your branding, custom decoration, secondary packaging, and product formulations

Include exit clauses specifying transition support if you need to switch systems

Understand the OBM controls the IP and can license the same system to competitors

Critical: Molds embody your entire design. Without ownership agreements, your design is essentially “open source”.

Red flags: Suppliers who refuse to discuss tooling ownership or provide vague answers about who else uses their platforms. For OBM relationships, also watch for suppliers who won’t define usage rights, competitive boundaries, or exit terms.

Choose OEM when:

Packaging is a core brand differentiator

You need strict performance standards

You’re building a hero product for long-term use

You have packaging expertise in-house

Choose ODM when:

Speed matters most (seasonal launches, trends)

You need multiple SKUs quickly

Budget is limited

You’re testing new markets

Choose OBM/branded systems when:

You need proven systems fast

Sustainability credentials matter more than unique structure

Best approach: Many brands use a hybrid—OEM for hero products, ODM for accessories and line extensions.