Requirement:

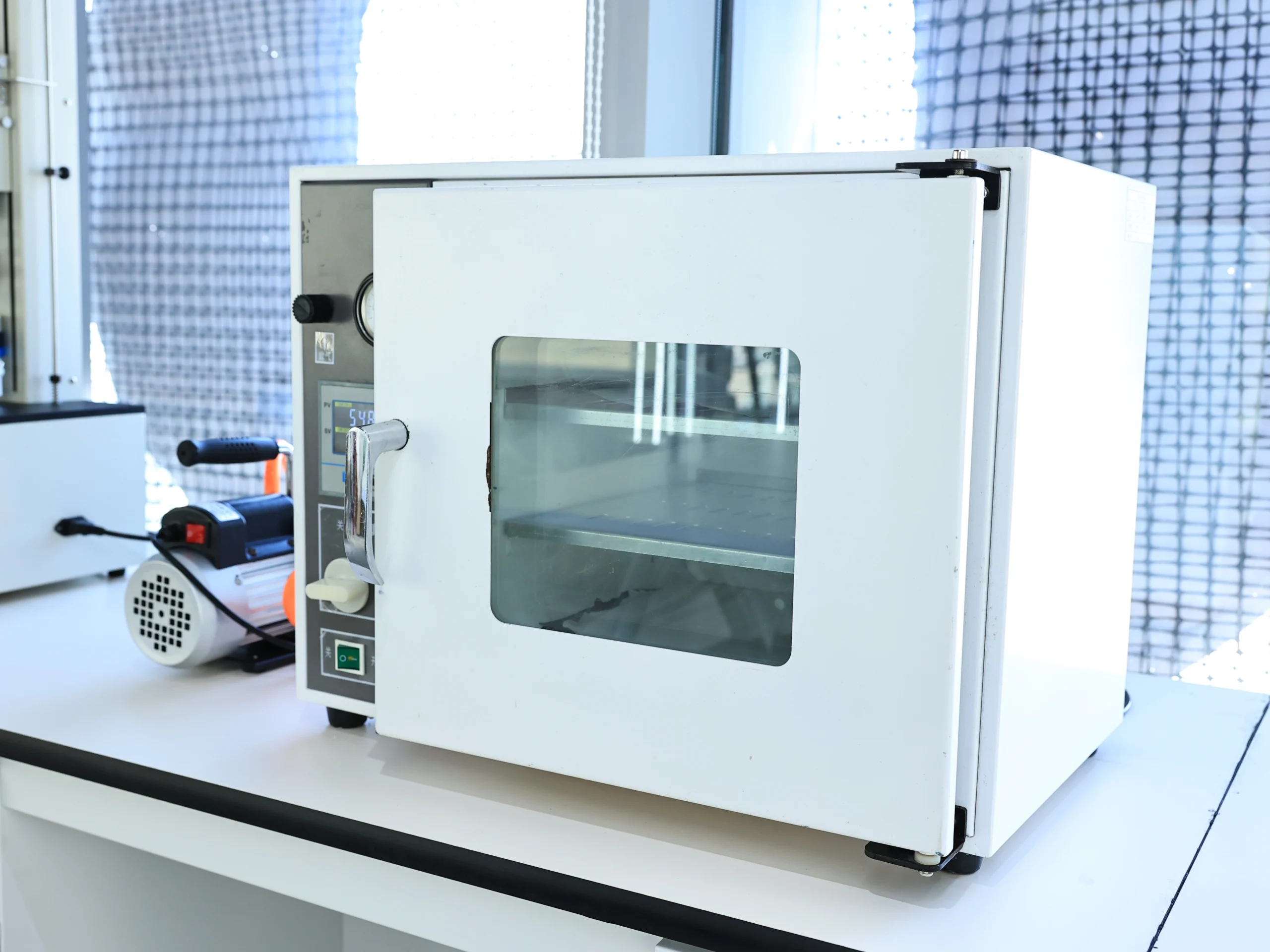

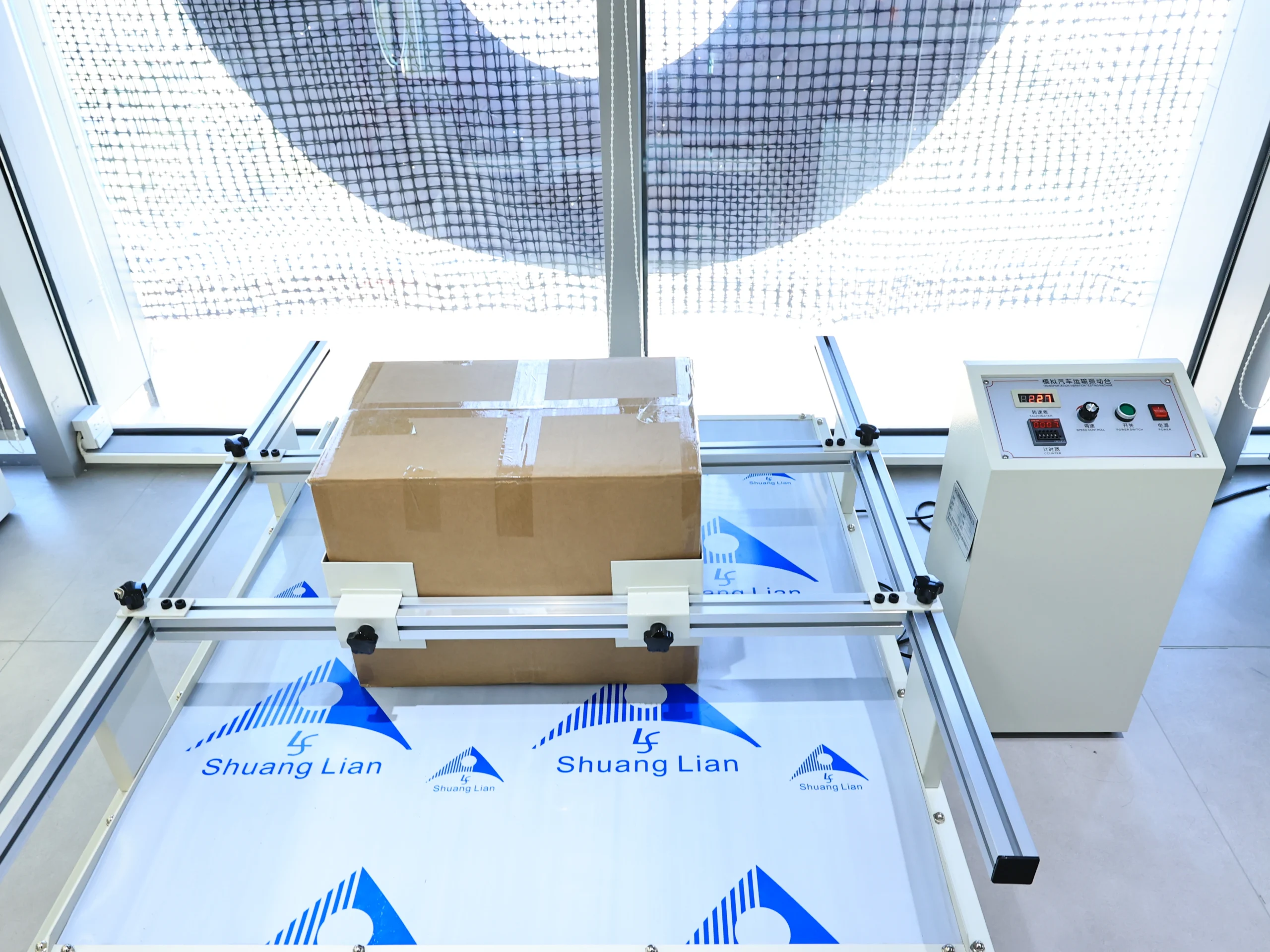

Specialty botanical product manufacturers require state-compliant child-resistant packaging meeting specific legal requirements for dried botanicals, concentrated extracts, and infused products. These companies need odor-control features, precise sizing options, custom branding capabilities, and packaging that maintains product freshness while ensuring regulatory compliance across different jurisdictions with varying specialty product packaging laws.

Jarsking’s Solution:

Jarsking delivers comprehensive specialty botanical packaging solutions including smell-proof child-resistant jars, concentrate containers, and dried product storage systems meeting state compliance requirements. Our containers feature advanced odor-barrier technology, UV protection, and airtight sealing with child-resistant mechanisms. We provide custom branding services, multiple size options (1g, 3.5g, 7g, 14g), and specialized concentrate jars with non-stick surfaces for optimal product preservation and regulatory adherence.