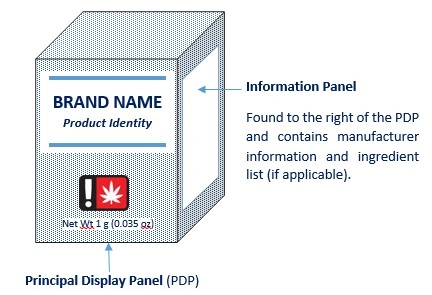

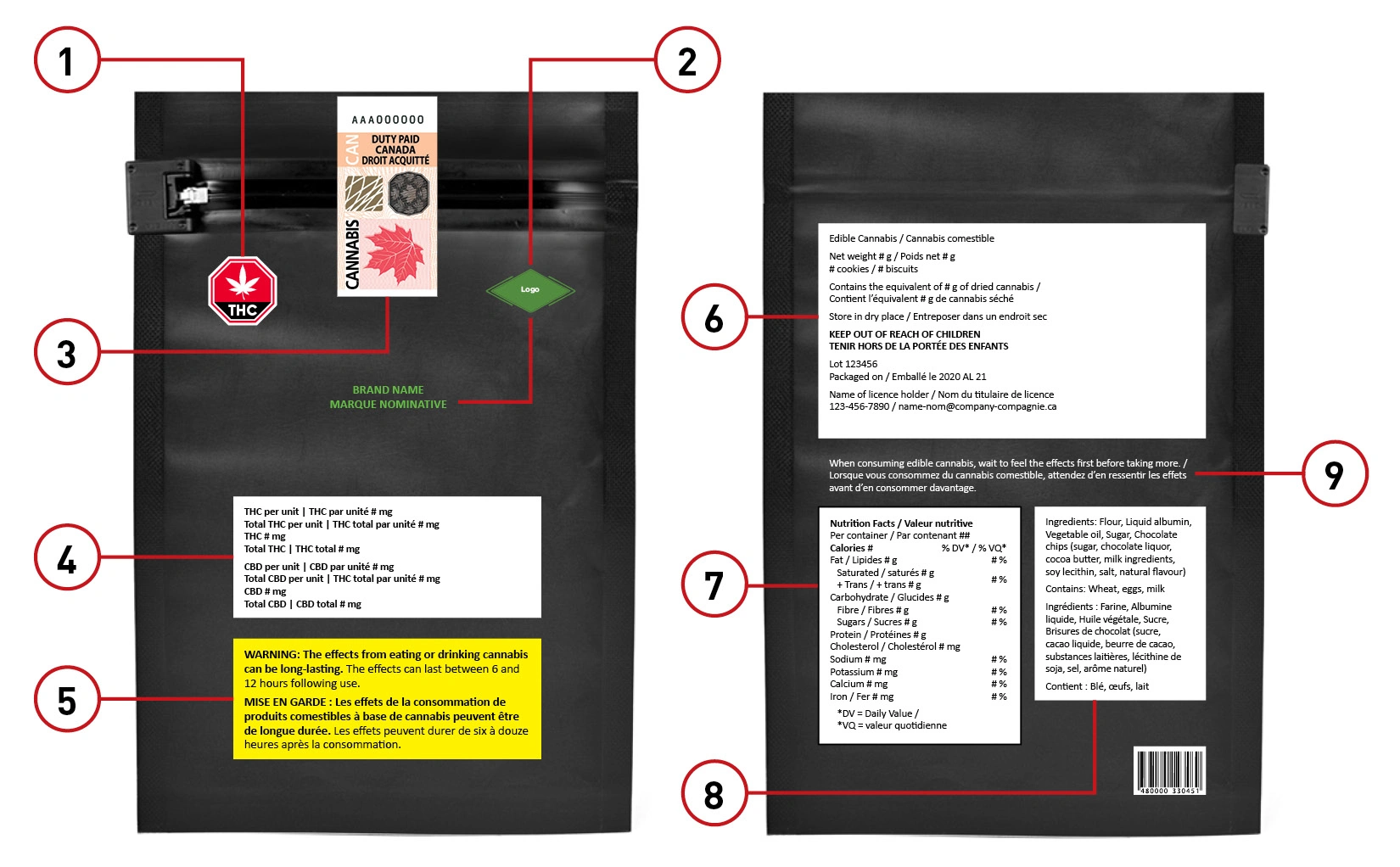

Jarsking provides a comprehensive range of cannabis packaging solutions tailored to meet the needs of the cannabis industry. We offer a variety of packaging products, including but not limited to child-proof ziplock Mylar bags, airtight glass jars, tamper-evident containers, and customizable pre-roll tubes. Each product is designed with industry standards and regulatory requirements in mind, ensuring that your cannabis products are stored safely, securely, and with a focus on product freshness. Our customizable options, from branding to unique packaging sizes, allow cannabis businesses to create distinct, recognizable packaging that appeals to customers while adhering to compliance standards.