The packaging industry stands at a critical crossroads as environmental concerns mount and consumer preferences shift toward more sustainable options. With global plastic waste reaching alarming levels and regulatory pressures intensifying, the need for innovative packaging solutions has never been more urgent. This comprehensive exploration delves into the cutting-edge materials and technologies transforming sustainable packaging, examining both their potential and limitations in creating a more environmentally responsible future.

Introduction

The packaging industry is undergoing a profound transformation driven by environmental imperatives, consumer demands, and regulatory pressures. Traditional packaging materials, particularly petroleum-based plastics, have created an environmental crisis that demands immediate and innovative solutions. The global packaging market, valued at approximately $1 trillion, is increasingly pivoting toward sustainable alternatives that minimize environmental impact while maintaining or enhancing functionality.

The need for material innovation in sustainable packaging

The environmental toll of conventional packaging has reached a critical point. Plastic pollution has infiltrated every corner of our planet, from the deepest ocean trenches to remote wilderness areas. With only about 9% of all plastic waste ever produced having been recycled, the remaining 91% accumulates in landfills or the natural environment. This reality has catalyzed an urgent search for innovative materials that can provide the functionality of traditional packaging while addressing end-of-life concerns.

Material innovation in sustainable packaging is not merely a response to environmental challenges but also to changing market dynamics. Consumers increasingly demand environmentally responsible packaging, with studies showing that a significant percentage are willing to pay a premium for products with sustainable packaging. Additionally, regulatory frameworks worldwide are evolving to restrict single-use plastics and promote circular economy principles, creating both challenges and opportunities for packaging innovation.

Balancing performance with environmental considerations

The fundamental challenge in sustainable packaging development lies in balancing performance requirements with environmental considerations. Packaging must still fulfill its primary functions-product protection, preservation, information provision, and convenience-while minimizing ecological impact. This delicate balance requires a nuanced understanding of material properties, manufacturing processes, and end-of-life scenarios.

Performance considerations include mechanical strength, barrier properties (against moisture, oxygen, light), shelf life extension, and compatibility with existing manufacturing and distribution systems. Environmental considerations encompass resource efficiency, renewable feedstock utilization, carbon footprint, biodegradability, recyclability, and potential for circular economy integration. The most promising innovations address both dimensions simultaneously, refusing to compromise functionality for sustainability or vice versa.

The role of technology in advancing sustainable materials

Technological advancement serves as the critical enabler for sustainable packaging innovation. From novel material formulations to advanced manufacturing processes, technology bridges the gap between laboratory concepts and commercial viability. Breakthroughs in material science, biotechnology, nanotechnology, and manufacturing processes are creating unprecedented opportunities for sustainable packaging development.

Digital technologies also play an increasingly important role in optimizing material usage, enhancing supply chain efficiency, and enabling traceability systems that support circular economy models. The convergence of material science with information technology creates synergies that accelerate the transition toward more sustainable packaging systems.

Inorganic Materials: Calcium Carbonate Revolution

Among the most promising sustainable packaging innovations is the emergence of calcium carbonate-based materials as viable alternatives to conventional plastics. This abundant mineral, found in limestone and marble deposits worldwide, is revolutionizing packaging through novel applications that leverage its unique properties and environmental benefits.

The science behind calcium carbonate-based packaging

Calcium carbonate (CaCO₃) serves multiple functions in sustainable packaging applications. Beyond its traditional role as a filler in plastic formulations, innovative approaches now utilize calcium carbonate as a primary structural component in packaging materials. These applications leverage calcium carbonate’s inherent properties, including rigidity, thermal stability, and compatibility with various binding agents.

The scientific breakthrough in calcium carbonate packaging involves creating composite materials that combine calcium carbonate particles with minimal amounts of binding polymers. These composites typically contain 60-80% calcium carbonate, significantly reducing the petroleum-based content compared to conventional plastics. The calcium carbonate particles are often surface-modified to enhance compatibility with binding agents and improve mechanical properties.

Functionalised calcium carbonates (FCCs) represent another innovative application, featuring high porosity and extended surface area consisting of hydroxyapatite and calcium carbonate crystal structures. These properties make FCCs excellent carriers for active substances such as essential oils, enabling controlled release in antimicrobial packaging applications.

Environmental benefits compared to conventional plastics

Calcium carbonate-based packaging offers several significant environmental advantages over conventional plastics:

Reduced carbon footprint: The production of calcium carbonate-based packaging typically requires less energy than petroleum-based plastics, resulting in lower greenhouse gas emissions. Additionally, the high mineral content reduces the amount of petroleum-derived polymers needed.

Abundance and accessibility: Calcium carbonate is one of the most abundant minerals on Earth, available in limestone deposits worldwide. This abundance ensures a stable, geographically distributed supply chain with minimal geopolitical vulnerabilities.

End-of-life options: Depending on the specific formulation, calcium carbonate-based packaging can be designed for recyclability, biodegradability under specific conditions, or even compostability. The mineral component returns to the earth in its natural form.

Reduced toxicity: Calcium carbonate is non-toxic and used in various food and pharmaceutical applications, making it a safe choice for food packaging compared to some conventional plastics that may contain potentially harmful additives.

Applications across different product categories

Calcium carbonate-based packaging materials have demonstrated versatility across numerous product categories:

Food packaging: Calcium carbonate composites are increasingly used for food containers, trays, and films, offering good barrier properties and food safety. The non-toxic nature of calcium carbonate makes it particularly suitable for direct food contact applications.

Beverage containers: Innovative calcium carbonate formulations are being developed for rigid containers, including bottles for water and other beverages, providing alternatives to PET and other conventional plastics.

E-commerce packaging: The rigidity and cushioning properties of calcium carbonate composites make them suitable for protective packaging applications in the rapidly growing e-commerce sector.

Personal care and cosmetics: The aesthetic qualities and printability of calcium carbonate-based materials make them attractive for premium packaging in the personal care and cosmetics industries.

Wood-Based Degradable Materials

Wood-derived materials represent one of the most promising frontiers in sustainable packaging innovation, offering renewable alternatives to petroleum-based plastics with unique aesthetic and functional properties.

Innovations in wood fiber packaging

Recent advances in wood fiber technology have dramatically expanded the potential applications of this renewable resource in packaging. Traditional paper and cardboard packaging has evolved into sophisticated engineered materials with enhanced performance characteristics.

Fibrease® wood foam exemplifies this innovation-a natural, low-carbon substitute for traditional polymer foams. This cellulose-based material is bio-based, sustainable, and recyclable with the paper stream, offering a compelling alternative to petroleum-derived packaging foams.

The manufacturing processes for these advanced wood fiber materials have also evolved significantly. Natural plant fiber-based packaging materials such as fiber-based foams, molded pulp packaging, fiber-based bottles, fiber-based flexible packaging, fiber-based blister packaging, and stretchable paper are emerging as sustainable alternatives to conventional plastic and non-biodegradable packaging.

Wood waste upcycling for packaging applications

A particularly promising approach involves upcycling wood waste streams into valuable packaging materials. This circular economy approach diverts waste from landfills while creating high-performance packaging solutions.

Wood residues from forestry operations, sawmills, and wood product manufacturing can be processed into fibers, cellulose nanocrystals, or other forms suitable for packaging applications. This approach not only reduces waste but also creates economic value from what would otherwise be low-value byproducts.

The environmental benefits of this approach are substantial. By utilizing waste streams, these packaging solutions minimize additional resource extraction while sequestering carbon that would otherwise be released through decomposition or incineration of wood waste.

Performance characteristics and limitations

Wood-based packaging materials offer distinctive performance characteristics that make them suitable for various applications:

Mechanical properties: Advanced wood fiber materials can provide excellent cushioning and shock absorption, making them suitable for protective packaging applications. Fibrease wood foam, for instance, has uniquely soft, flexible, and lightweight attributes that mirror polyurethane foam while delivering outstanding thermal performance that exceeds expanded polystyrene bead foam.

Thermal insulation: Some wood-based materials offer exceptional thermal insulation properties, with R-values exceeding those of conventional petroleum-based foams. This makes them particularly valuable for temperature-sensitive product packaging.

Versatility: Wood-based materials can be processed using various fabrication methods, including die-cutting, gluing, coating, laminating, skiving, and water jet cutting, enabling diverse packaging designs.

However, these materials also face certain limitations:

Moisture sensitivity: Many wood-based materials remain vulnerable to moisture, potentially limiting their application in high-humidity environments or for liquid products.

Barrier properties: Achieving the oxygen and moisture barrier properties required for certain food applications remains challenging without additional treatments or coatings.

Scale and cost: While advancing rapidly, the production scale and cost efficiency of some advanced wood-based materials have not yet reached parity with conventional plastics.

Aesthetic qualities and consumer perception

Wood-based packaging offers distinctive aesthetic qualities that resonate with contemporary consumer preferences for natural, authentic materials. The tactile experience, visual warmth, and perceived naturalness of wood-based packaging create positive associations with sustainability and craftsmanship.

Consumer perception studies indicate that wood-based packaging is generally viewed as environmentally friendly, premium, and authentic. These positive associations can enhance brand perception and justify price premiums in certain market segments.

The natural variations in wood-based materials can also be leveraged as a design feature, creating packaging with unique character that stands out in retail environments increasingly dominated by homogeneous plastic packaging.

Marine Degradable Materials

The crisis of marine plastic pollution has spurred focused research on materials specifically designed to safely degrade in marine environments, addressing one of the most challenging aspects of plastic pollution.

The specific challenge of marine plastic pollution

Marine plastic pollution represents a distinct and particularly troubling dimension of the global waste crisis. An estimated 8 million metric tons of plastic waste enter the oceans annually, with devastating consequences for marine ecosystems, wildlife, and potentially human health through the food chain.

Conventional plastics persist in marine environments for hundreds of years, fragmenting into microplastics that permeate the entire marine ecosystem. These microplastics have been detected from the deepest ocean trenches to Arctic ice, demonstrating the global scale of the problem.

The challenge is compounded by the unique conditions of marine environments-low temperatures, limited oxygen, variable salinity, and diverse microbial communities-which significantly slow the degradation of most biodegradable materials designed for terrestrial environments.

Materials designed to safely degrade in marine environments

Researchers have developed several promising approaches to creating marine-degradable materials:

Seawater-degradable polymers: These materials are specifically designed to degrade in seawater through various mechanisms including hydrolysis, photodegradation, and biodegradation. They represent a potential alternative to commodity polymers in certain applications, particularly those with high risk of marine leakage.

Polyhydroxyalkanoates (PHAs): These biopolymers, produced by bacterial fermentation, have emerged as promising candidates for marine-degradable packaging due to their biobased origin, biodegradability in marine environments, and biocompatibility. PHAs stand out for their good mechanical and medium gas permeability properties, making them suitable for food packaging applications.

Modified conventional polymers: Research has explored modifying conventional polymers like polypropylene with additives such as starch, metal catalysts, auto-oxidants, or plasticizers to enhance their degradability in marine environments. For example, studies have examined unstabilized polypropylene-starch blends with metal catalysts that show surface erosion due to microbial activity when exposed to marine environments.

Zinc oxide nanocomposites: Innovative approaches combine biodegradable polymers like PHAs with zinc oxide nanoparticles to create materials with enhanced antimicrobial properties and improved mechanical and barrier characteristics, potentially suitable for marine-degradable packaging applications.

Testing standards and certification for marine degradability

The development of reliable testing standards and certification systems for marine degradability remains a work in progress. Unlike industrial composting, which has established standards (such as ASTM D6400 or EN 13432), marine degradation testing faces challenges due to the variable and complex nature of marine environments.

Current testing approaches include:

Laboratory simulations: Controlled laboratory tests that simulate marine conditions, including temperature, salinity, microbial presence, and mechanical stress.

Field testing: Real-world exposure tests in various marine environments, including surface water, deep water, and sediment conditions.

Standardization efforts: Organizations such as ASTM International and ISO are working to develop standardized testing protocols specifically for marine degradability.

The lack of universally accepted standards creates challenges for material developers, regulators, and consumers seeking to identify truly marine-degradable options. Certification systems that can reliably verify marine degradability claims remain limited but are crucial for market development and consumer confidence.

Current applications and future potential

Current applications of marine-degradable materials remain relatively limited but include:

Fishing gear: Nets, lines, and other fishing equipment with high risk of loss at sea.

Coastal and marine tourism items: Single-use items commonly used in coastal tourism, such as straws, cups, and food containers.

Maritime industry consumables: Packaging and single-use items used in shipping, offshore operations, and other maritime activities.

The future potential for marine-degradable materials extends to numerous applications where the risk of marine leakage is significant or where recovery for recycling is challenging. As performance improves and costs decrease, these materials could replace conventional plastics in a wide range of applications, particularly in coastal regions and maritime industries.

Converting Non-Biodegradable to Biodegradable Polymers

A promising approach to addressing plastic pollution involves modifying conventional, non-biodegradable polymers to enhance their biodegradability while maintaining their valuable performance characteristics.

The science of polymer modification for biodegradability

The fundamental challenge in polymer modification lies in introducing biodegradable elements into otherwise resistant polymer structures without compromising essential performance properties. Several scientific approaches have emerged:

Blending with biodegradable polymers: Incorporating biodegradable polymers such as starch, cellulose, or biodegradable polyesters into conventional polymer matrices creates materials that can partially biodegrade, with the biodegradable component creating pathways for microbial access and degradation.

Pro-oxidant additives: These additives catalyze the oxidation of polymer chains when exposed to UV light, heat, or mechanical stress, breaking long polymer chains into shorter, potentially biodegradable fragments.

Enzyme-responsive elements: Incorporating chemical bonds that specific enzymes can target allows for biodegradation under specific environmental conditions where those enzymes are present.

Copolymerization: Creating copolymers that combine conventional monomers with biodegradable monomers results in materials with controlled degradation properties.

How PP (Polypropylene) can be made biodegradable

Polypropylene (PP), one of the most widely used plastics globally, presents particular challenges for biodegradation due to its chemical structure. However, several approaches have shown promise in enhancing PP biodegradability:

PP-starch blends: Research has demonstrated that blending PP with starch can enhance biodegradability under certain conditions. Studies have examined unstabilized polypropylene-starch blends with or without additives such as metal catalysts, autooxidants, and metal-containing plasticizers. While blends without additives showed limited degradation in seawater, those containing metal catalysts, auto-oxidants, or plasticizers exhibited surface erosion due to microbial activity when exposed to marine environments.

Surface modification: Modifying the surface of PP through techniques such as plasma treatment, UV irradiation, or chemical oxidation can create reactive sites that facilitate microbial attachment and enzymatic degradation.

Incorporation of biodegradable fibers: Adding natural fibers like microcrystalline cellulose (MCC) to PP can improve not only mechanical properties but also potentially enhance biodegradability. Surface modification of these fibers, such as grafting sunflower oil ethyl esters onto MCC, can improve compatibility with the PP matrix while maintaining biodegradation potential.

Advanced oxidation technologies: Recent research has explored sustainable depolymerization/degradation of PP microplastics using advanced oxidation technologies (AOT) such as ozonation, sonochemistry, or photocatalysis, aiming to make the PP degradation process more environmentally sustainable.

The role of catalysts in biodegradation processes

Catalysts play a crucial role in accelerating the biodegradation of modified polymers:

Metal catalysts: Compounds containing transition metals such as cobalt, manganese, or iron can catalyze oxidation reactions that break polymer chains. For example, cobalt (III) acetylacetonate has been studied as a catalyst in polypropylene-starch blends exposed to marine environments.

Enzymatic catalysts: Specific enzymes can target vulnerable bonds in modified polymers, accelerating their breakdown into smaller, more readily biodegradable fragments.

Photocatalysts: Materials such as titanium dioxide can catalyze degradation reactions when exposed to light, particularly UV radiation, enhancing the breakdown of polymer chains.

Microbial catalysts: Certain microorganisms produce enzymes specifically capable of degrading modified polymers, particularly those containing natural components like starch or cellulose.

Performance trade-offs and considerations

Modifying conventional polymers for biodegradability inevitably involves performance trade-offs that must be carefully considered:

Mechanical properties: Adding biodegradable components or introducing vulnerable bonds often reduces tensile strength, impact resistance, or flexibility. For example, calcium carbonate particles filled homopolymer polypropylene shows decreased tensile strength with increasing loading levels of CaCO3 particles, while tensile and flexural modulus increase significantly.

Processing challenges: Modified polymers may require different processing parameters or equipment modifications, potentially increasing manufacturing complexity and cost.

Shelf life and stability: Enhanced biodegradability may reduce product shelf life or stability under certain storage conditions, necessitating improved packaging or storage systems.

Cost implications: Additives, catalysts, and modified processing requirements typically increase material costs, though these may be offset by environmental benefits and consumer willingness to pay premiums for sustainable options.

Verification challenges: Ensuring that modified polymers actually biodegrade as intended in real-world conditions remains challenging, requiring sophisticated testing protocols and potentially third-party verification.

Emerging Technologies in Material Processing

Advanced processing technologies are revolutionizing sustainable packaging manufacturing, enabling new material formulations, improved performance, and reduced environmental impact.

Advanced manufacturing techniques for sustainable materials

Innovative manufacturing approaches are expanding the possibilities for sustainable packaging materials:

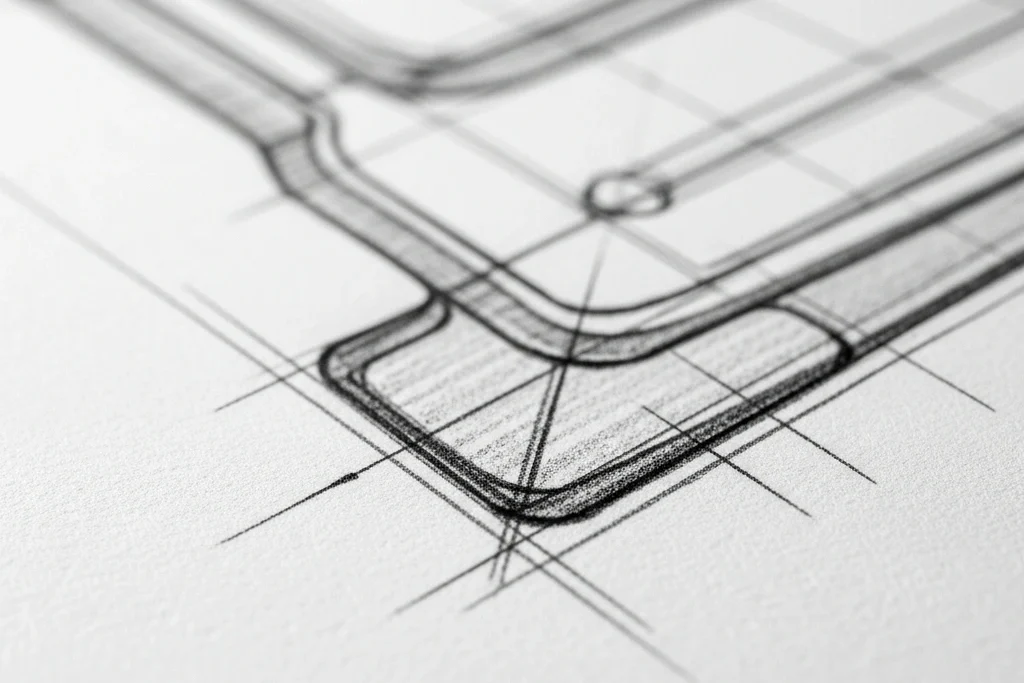

Additive manufacturing: 3D printing technologies enable complex, customized packaging structures with minimal material waste. These technologies are particularly valuable for prototyping and small-batch production of specialized sustainable packaging solutions.

Supercritical fluid processing: Using supercritical CO2 as a processing medium allows for the creation of novel material structures, such as foams and composites, without environmentally harmful blowing agents or solvents.

Electrospinning and centrifugal fiber spinning: These techniques enable the production of ultra-fine fibers from biodegradable polymers, creating materials with unique properties for specialized packaging applications. Research on polyhydroxyalkanoate/ZnO nanocomposites has explored these methods for producing films or fibers with specific properties.

Reactive extrusion: This process combines chemical reactions with traditional extrusion, enabling in-line modification of polymers and the creation of novel sustainable materials with enhanced properties.

Reducing energy consumption in production processes

Energy efficiency in manufacturing represents a critical dimension of sustainable packaging development:

Low-temperature processing: Developing materials that can be processed at lower temperatures significantly reduces energy consumption. Biodegradable polymers often offer advantages in this regard compared to conventional high-temperature thermoplastics.

Solvent-free systems: Eliminating or reducing solvent use in coating and laminating processes not only reduces environmental impact but also decreases energy requirements for solvent recovery or evaporation.

Precision energy application: Technologies that apply energy precisely where needed, such as ultrasonic welding or laser cutting, minimize overall energy consumption compared to traditional heating or mechanical processing methods.

Renewable energy integration: Packaging manufacturers are increasingly integrating renewable energy sources into production facilities, further reducing the carbon footprint of sustainable packaging materials.

Innovations in material formulations

Material science breakthroughs are creating unprecedented opportunities for sustainable packaging:

Nanocomposites: Incorporating nanomaterials into biodegradable polymers can dramatically enhance properties such as barrier performance, mechanical strength, and antimicrobial activity. For example, polyhydroxyalkanoate/ZnO nanocomposites combine the biodegradability of PHAs with the antimicrobial properties of zinc oxide nanoparticles.

Bio-based additives: Plant-derived plasticizers, stabilizers, and processing aids are replacing petroleum-based additives in sustainable packaging formulations, further reducing fossil resource dependence.

Multifunctional materials: Advanced formulations increasingly incorporate multiple functionalities-such as oxygen scavenging, antimicrobial properties, or moisture control-into single materials, reducing the need for complex multilayer structures that hinder recyclability.

Stimuli-responsive materials: Packaging materials that respond to environmental conditions such as temperature, humidity, or pH offer new possibilities for extending shelf life while maintaining sustainability credentials.

Quality control and consistency challenges

Maintaining consistent quality in sustainable materials presents unique challenges:

Natural material variability: Bio-based materials often exhibit greater batch-to-batch variability than petroleum-derived alternatives, requiring more sophisticated quality control systems.

Process parameter sensitivity: Many sustainable materials have narrower processing windows than conventional plastics, demanding precise control of manufacturing parameters.

Performance testing complexity: Evaluating properties such as biodegradability, compostability, or marine degradability requires specialized testing protocols that may be time-consuming and complex.

Supply chain traceability: Ensuring the sustainability credentials of raw materials necessitates robust traceability systems throughout the supply chain.

Case Study: RCE-P Outdoor Degradable Film

Biodegradable agricultural films represent one of the most promising applications of sustainable polymer technology, addressing the significant environmental challenge of plastic accumulation in agricultural soils.

Technical specifications and performance metrics

Biodegradable agricultural films, such as those based on poly-(butylene adipate-co-butylene terephthalate) (PBAT), poly-carbon dioxide (PCO2), and poly propylene carbonate (PPC), offer specific technical advantages:

Mechanical properties: These films provide sufficient tensile strength and elongation to withstand agricultural conditions while remaining thin enough for cost-effectiveness. The films must balance durability during the growing season with controlled degradation afterward.

Optical properties: Many biodegradable films offer excellent light transmission and the ability to modify light spectrum for optimal plant growth, comparable to conventional plastic films.

Soil interaction: Unlike conventional plastic mulch, biodegradable films can be designed to interact beneficially with soil ecosystems. Studies show that biodegradable films can significantly affect soil nutrient content, with PBAT films increasing alkali-hydrolyzed nitrogen at various growth stages.

Plant growth effects: Research demonstrates that biodegradable films can promote plant growth and development. For example, PCO2 biodegradable film has been shown to significantly increase plant height at seedling and growth stages, stem diameter at growth stage, and leaf area index at fruiting stage compared to uncovered controls.

Degradation mechanism and environmental factors

The degradation of biodegradable agricultural films involves complex interactions between material properties and environmental conditions:

Degradation rates: Different biodegradable films exhibit varying degradation rates under field conditions. Studies comparing PBAT, PCO2, and PPC films found that PBAT degraded most rapidly, followed by PPC, with PCO2 showing the slowest degradation.

Environmental triggers: Degradation is typically initiated by a combination of UV radiation, heat, moisture, and microbial activity. The relative importance of these factors varies by material formulation and local conditions.

Soil incorporation: As films degrade, they fragment and become incorporated into the soil, where further biodegradation occurs. This process must be complete enough to avoid microplastic accumulation while maintaining film functionality during the growing season.

Soil health impacts: Research indicates that properly designed biodegradable films can degrade without negative impacts on soil health and may even provide benefits. The three biodegradable films (PBAT, PCO2, and PPC) have been shown to significantly affect soil nutrient content in positive ways.

Agricultural applications and benefits

Biodegradable agricultural films offer numerous benefits across various applications:

Mulch films: These films suppress weeds, conserve soil moisture, and modify soil temperature while eliminating the labor-intensive and often incomplete removal of conventional plastic mulch. Studies show that biodegradable mulch films can significantly improve crop yields compared to uncovered controls.

Low tunnel covers: Biodegradable films used for season extension and crop protection eliminate the waste associated with conventional plastic covers while providing comparable growing benefits.

Soil fumigation films: Biodegradable films for soil fumigation offer improved environmental profiles compared to conventional films while maintaining effective pest management.

Crop-specific applications: Tailored biodegradable films address the specific needs of different crops and growing systems, from vegetables to berries to tree seedlings.

Cost considerations and market adoption

Despite their environmental benefits, biodegradable agricultural films face several market challenges:

Price premium: Biodegradable films typically cost more than conventional plastic films, though this gap is narrowing as production scales increase and petroleum prices rise.

Performance perceptions: Some growers remain skeptical about biodegradable film performance, particularly regarding durability and consistent degradation timing.

Regional variability: Adoption rates vary significantly by region, influenced by regulatory frameworks, environmental awareness, and economic factors.

Education and demonstration needs: Successful market adoption requires education about proper use and realistic expectations regarding degradation timeframes and patterns.

Conclusion

The innovation pipeline for sustainable packaging materials continues to expand, driven by environmental imperatives, consumer demand, and technological advancement. From calcium carbonate composites to advanced wood-based materials, from marine-degradable polymers to modified conventional plastics, the diversity of approaches reflects both the complexity of the challenge and the creativity of potential solutions.

The innovation pipeline for sustainable packaging materials

The future of sustainable packaging innovation appears robust, with several promising directions:

Biomimicry: Drawing inspiration from natural packaging systems, such as fruit peels or eggshells, to create high-performance, fully biodegradable materials.

Hybrid materials: Combining the strengths of different sustainable material types-such as biopolymers with inorganic components-to achieve optimal performance profiles.

Closed-loop systems: Developing materials specifically designed for efficient collection and recycling or composting within existing or emerging infrastructure.

Smart sustainable packaging: Integrating digital technologies with sustainable materials to enhance functionality, extend shelf life, and facilitate proper end-of-life management.

Balancing performance, cost, and environmental impact

The sustainable packaging industry continues to navigate the complex balance between performance requirements, cost constraints, and environmental objectives. This balance varies by application, with different priorities for food preservation, luxury goods, e-commerce, or industrial packaging.

Successful innovations increasingly recognize that these factors are not necessarily in opposition-enhanced performance can reduce material requirements and costs while improving environmental profiles. Similarly, designing for specific end-of-life scenarios can simultaneously enhance environmental benefits and reduce system costs.

The most promising approaches take a systems perspective, considering the entire lifecycle from raw material sourcing through manufacturing, distribution, use, and end-of-life management. This holistic view enables identification of optimal solutions that balance multiple objectives rather than maximizing any single dimension.

Recommendations for brands exploring innovative materials

Brands seeking to incorporate innovative sustainable packaging materials should consider several strategic approaches:

Pilot testing: Begin with limited-scale pilot projects to evaluate real-world performance, consumer response, and supply chain compatibility before full-scale implementation.

Collaborative development: Partner with material suppliers, packaging converters, and waste management entities to ensure system-wide compatibility and optimization.

Consumer education: Invest in clear, transparent communication about material choices, environmental benefits, and proper disposal to maximize both perception benefits and actual environmental impact.

Lifecycle assessment: Conduct rigorous lifecycle assessments comparing innovative materials with conventional alternatives to ensure that environmental benefits are genuine and significant.

Phased implementation: Develop a strategic roadmap for sustainable packaging implementation that acknowledges current constraints while establishing clear pathways toward more ambitious future goals.

The transition to truly sustainable packaging requires patience, persistence, and partnership across the value chain. By embracing innovation while maintaining pragmatic perspectives on performance requirements and system constraints, brands can make meaningful progress toward packaging systems that protect products, please consumers, and preserve the planet for future generations.

As we continue this journey, the most successful approaches will likely be those that recognize packaging not as an isolated product but as an integral component of broader product and service systems designed for sustainability from inception to end-of-life. This systems thinking, combined with material and technological innovation, offers the most promising path toward a future where packaging enhances rather than diminishes environmental and social wellbeing.