· LATEST DESIGN

· LATEST DESIGN

· LATEST DESIGN

· LATEST DESIGN

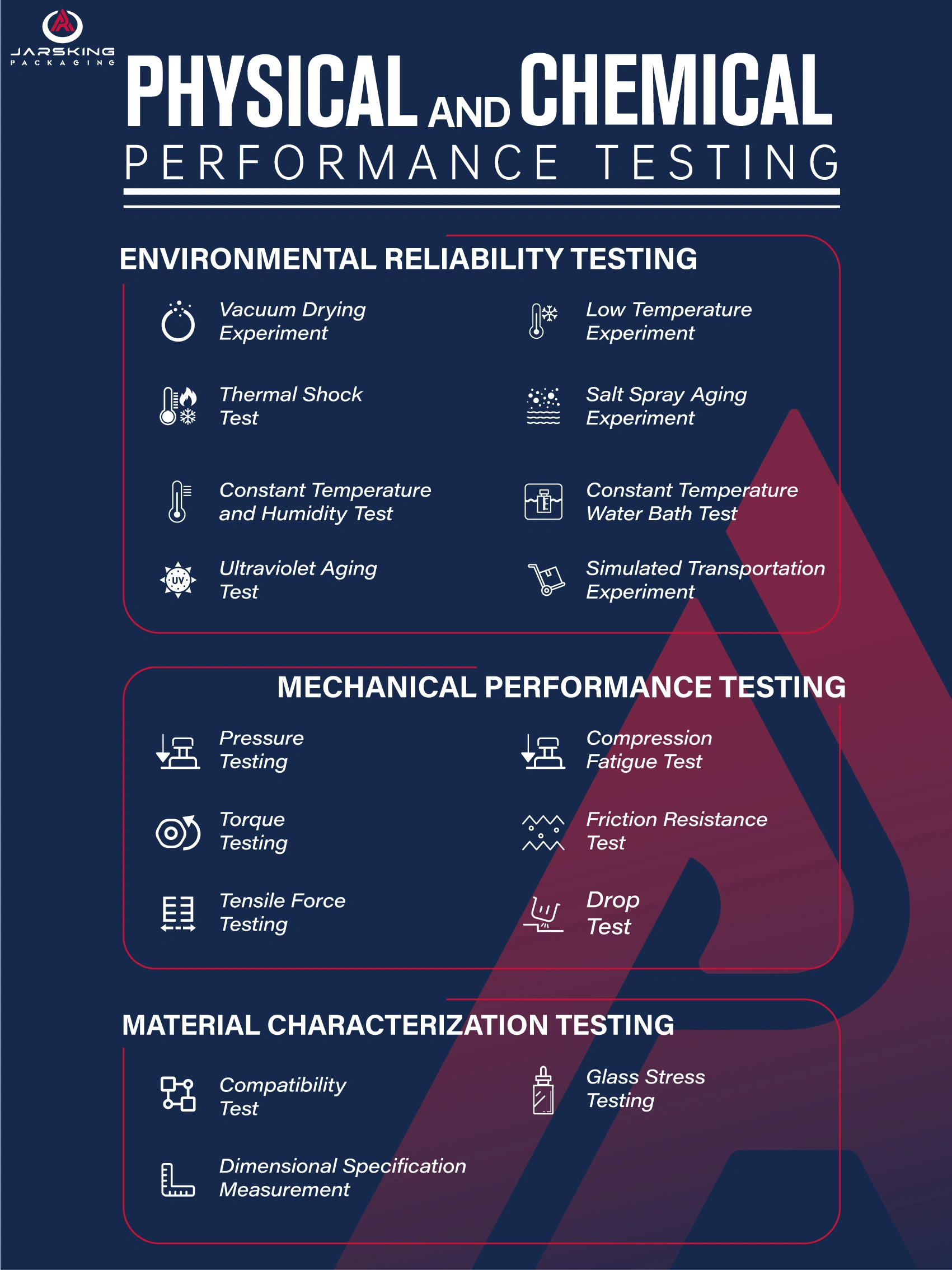

Jarsking covers all cosmetics,cannabis and perfume markets. Ask custom solutions here!

· EFFICIENCY+

· LATEST DESIGN

The world’s go-to cosmetic packaging factory for custom branding. Talk to Jarsking Team